Concrete Mix Ratios (Cement, Sand, Gravel)

Preparing the right mix

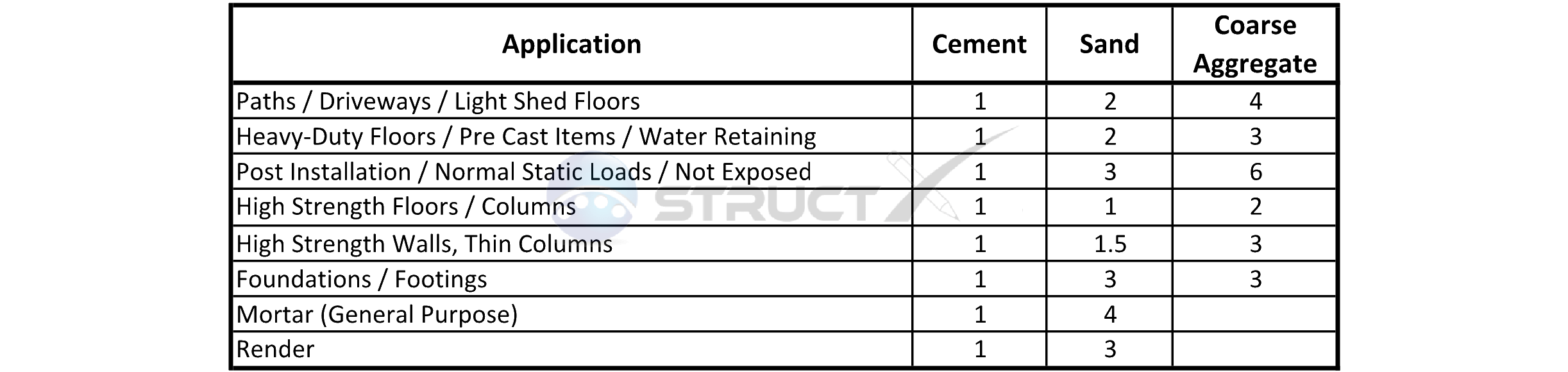

Depending on the application concrete mix design can be complex. The below table gives a basic indication of the mix ratios used for different purposes but should be used as a guide only. Some additional things to consider when finding a suitable mix design include but are in no way limited to the following:

- Water/cement ratio theory states that for a given combination of materials and as long as workable consistency is obtained, the strength of concrete at a given age depends on the w/c ratio.

- The lower the w/c ratio, the higher the concrete strength.

- All materials used for a design including the water quality should be to a high standard. A general rule of thumb is, if the water is palatable then it is suitable for mixing concrete.

Mortar Mix Ratios (Cement, Sand, Gravel)

Mortar Types and Uses

Typically used as the compound for joining masonry, stone or ceramic units together, mortar is made by combining cement, lime and sand. Mortar typically has a higher water to cement ratio when compared with concrete which allows greater workability and is required to form mortars bonding properties. Typical mortar types are discussed below and a basic guide to mix ratio's and expected minimum compressive strengths has been provided.

- Type M Mortar: Typically used with stone construction as it has the strongest minimum compressive strength of the mortar types. It is ideally suited to below ground applications and areas where high vertical or lateral loads are present such as retaining walls.

- Type S Mortar: A medium strength mortar suited to below ground applications such as shallow retaining walls and exterior projects where moderate loads can be expected. Type S mortar is also ideal for areas where masonry or other block work is in contact with the ground, such as pavers.

- Type N Mortar: A general purpose mortar it is the most common type available with good all round characteristics. It is used for above ground exterior applications and load bearing walls. Type N mortar provides lower bonding and lateral strength when compared to Type S and M mortar types but has considerably more flex which prevents cracking of any block-work or masonry units. A good all round mortar for general purpose applications.

- Type O Mortar: A low strength mortar intended for interior non-loading bearing applications such as aesthetic repair work to existing damaged mortar. It is easier to work with than the stronger type mortars and is sometimes used in conjunction with low strength masonry units and sandstone.

- Type K Mortar: Having the lowest compressive strength of the traditional mortar types, this type of mortar does not provide any additional strength or bearing capacity and is only adopted where very soft or fragile masonry or stone is required. It is used for historical preservation projects and is also suitable for minor repair work.

Additional Resources

- ACI Committee 211. Standard Practice for Selecting Proportions for Normal, Heavyweight and Mass Concrete. USA. 2002. Print.

- American Concrete Institute. Proportioning Concrete Mixes. Detroit. 1974. Print.

- Base Concrete. (n.d.). Base Concrete Different types of concrete grades and their uses no date. (Author post). Retrieved from https://www.baseconcrete.co.uk/different-types-of-concrete-grades-and-their-uses/

- Cement Concrete & Aggregates. Concrete Basics: A Guide to Concrete Practice. Australia. Print and Published in "CCAA website".

- Prasiddha. (2016). Concrete mix ratios. Civile Blog Retrieved from http://www.civileblog.com/concrete-mix-ratio/