StructX > Design Tables > Concrete Reinforcement

A Complimentary Pairing

Concrete is well known for its ability to resist large compressive forces, that is, concrete can be squeezed or squashed with fairly large loads without any noticeable effect. Unfortunately, when it comes to resisting tensile forces or being pulled apart concrete, especially in an un-reinforced state, is rarely a suitable choice of material. Adding steel which is weak in compression but capable of withstanding large tensile or pulling forces to concrete creates a composite material known commonly as reinforced concrete. Reinforced concrete combines the compressive strength of concrete with the tensile strength of steel to form a material that is both tough and durable.

The following tables have been provided for easy access to reinforcement properties. For those who are unfamiliar with concrete design and/or placement expert advice should always be sought. Well designed and placed concrete will last a lifetime plus some, but poorly laid concrete can be problem prone.

Reinforcement Design Areas

- The above table gives values for the cross-sectional area of reinforcement bars based on the number of bars being used.

- The above table gives values for the cross-sectional area of reinforcement bars per meter based on the spacing of bars under consideration.

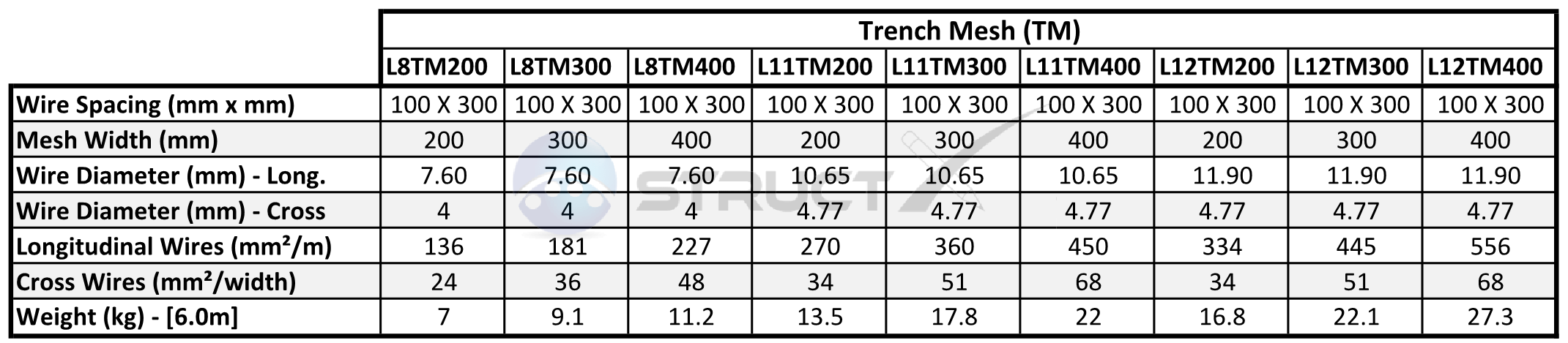

Common Mesh Sizes

Mesh sizes for typical sized metric sheets have been provided in the below tables along with expected properties.

Stress Development & Lap Lengths

Assumptions and Limitations

The following table can be used as a basic guide for determining the lengths required for overlapping reinforcement, to be confirmed via detailed calcs before being finalised. The following assumptions have been made:

- For "narrow" type elements such as slender columns and webs of beams, the clear cover is the minimum distance from the bar under consideration to the closest adjacent concrete surface.

- A minimum distance of 3 x the largest bar diameter shall be adopted between each pair of bars being sliced in "narrow" type elements.

- A longer overlap may be required if the clear distance between adjacent parallel bars is smaller than twice the clear concrete cover.

- The clear concrete cover shall not be less than the largest bar diameter.

- A maximum 300mm centre to centre spacing between adjacent parallel bars being spliced shall be adopted.

- Horizontal reinforcement bars do not have more than 300mm of cast concrete below them.

- The maximum sized bar to be used in 20MPa concrete does not exceed 20mm.

- Exposure classifications are to be in accordance with AS3600.

The above picture shows the position of the overlap referred to in the below table.

Values have been rounded up to the nearest 10mm

Reinforcement grade straight D500N

- Lsy.tb: Is the basic development length calculated in accordance with AS3600:2009 (Cl 13.1.2.2).

- Lsy.t: Is the refined development length calculated in accordance with AS3600:2009 (Cl 13.1.2.3).

- Lsy.tb.lap: Is the lapped splices for bars in tension calculated in accordance with AS3600:2009 (Cl 13.2.2).

- Lsy.tb.lap: Is the refined lapped splices for bars in tension calculated in accordance with AS3600:2009 (Cl 13.2.2).

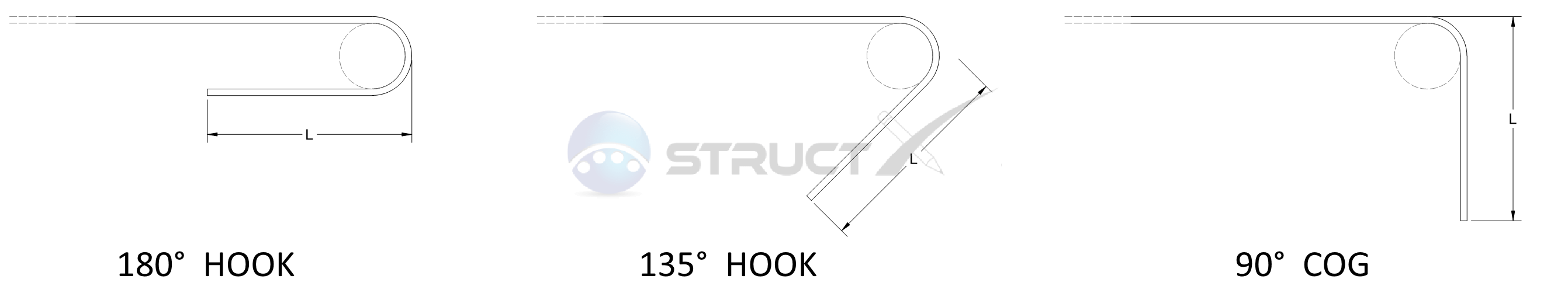

Typical Hooks and Cogs

Table based on AS3600:2009 Cl 13.1.2.7